Rotary joints are an important component in drive technology that serve to transfer motion from a stationary part to a moving part. They enable moving parts in machines and plants to rotate smoothly against each other. There are various types of rotary joints such as ball bearings, roller bearings, plain bearings, and universal joints, which differ depending on the application and load.

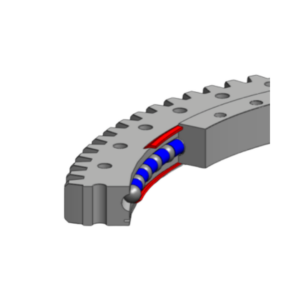

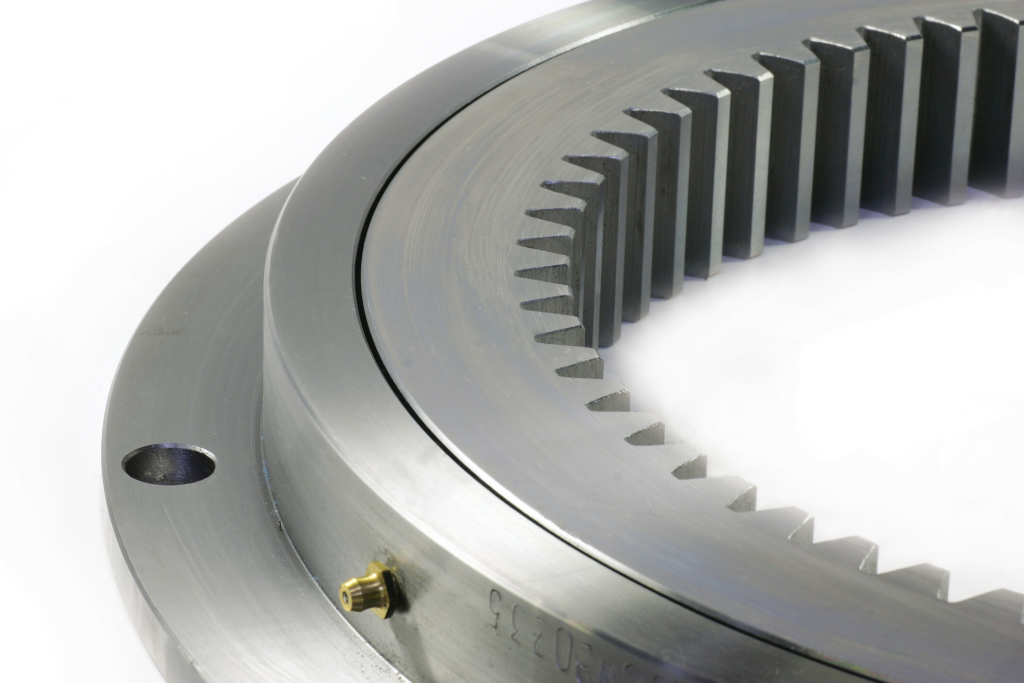

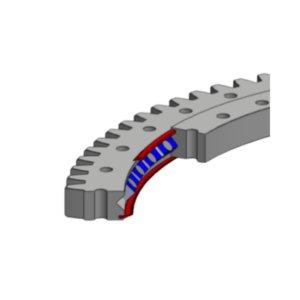

Single-row ball slewing bearings, available either internally, externally, or non-toothed.

Standard four-point bearings of the 01 series are among the most commonly used series. Diameter ranges from 120 mm to 6300 mm – with hardened or unhardened teeth achievable. Four-point contact raceway geometry, a preloaded raceway system, centering, special seals, and various spacers or cages for applications up to 350°C are available.

The L series comprises lightweight profile series, flange bearings with external, internal, or non-toothed versions. The raceway diameter ranging from 310 mm to 1455 mm is included in our standard program. Any design is also available with double bores, narrowed to preloaded bearing play, up to precision quality for machine tools.

Applications: Excavators, deep drilling machines, and other construction machinery, welding construction, machine and plant engineering.

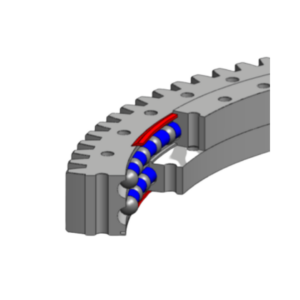

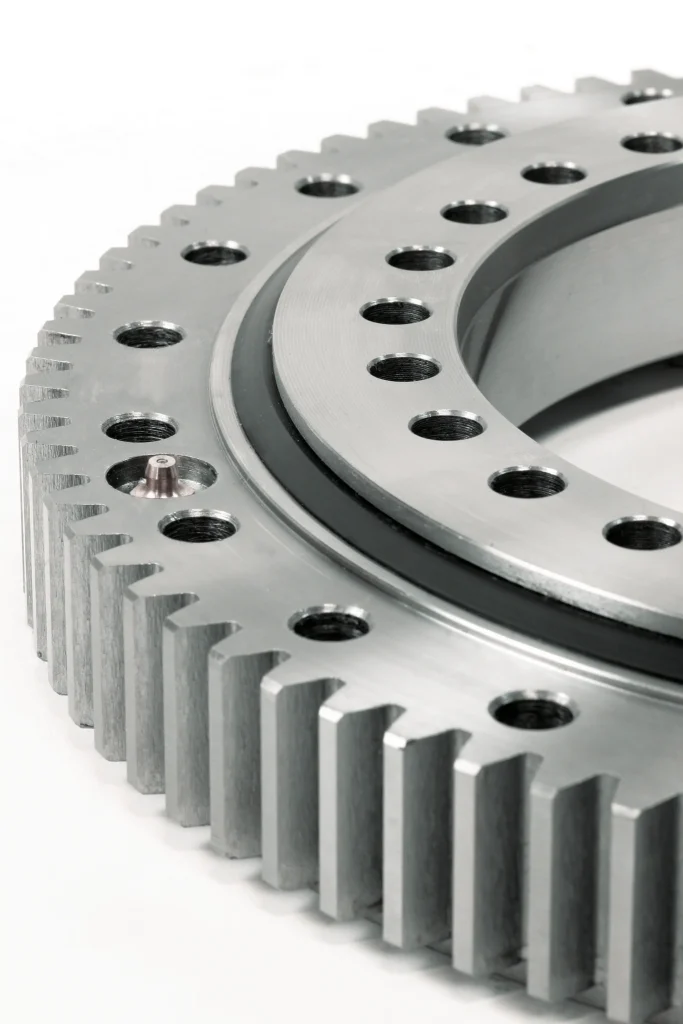

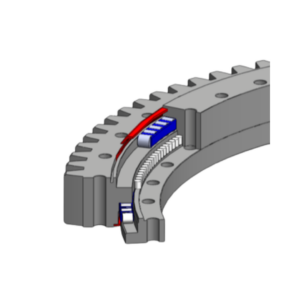

Double-row ball slewing bearings are designed for heavy loads. This series is insensitive to deviations in the connecting structure and has a higher static load capacity than the equivalent cross roller slewing bearing.

Therefore, this CRB product is particularly suitable for demanding applications such as wind turbines.

The standard range of our eight-point bearings is from 500 mm to 4500 mm in diameter.

Areas of application: wind turbines, cranes, construction machinery, machine and plant engineering.

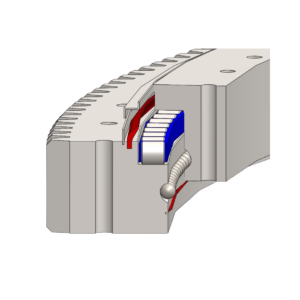

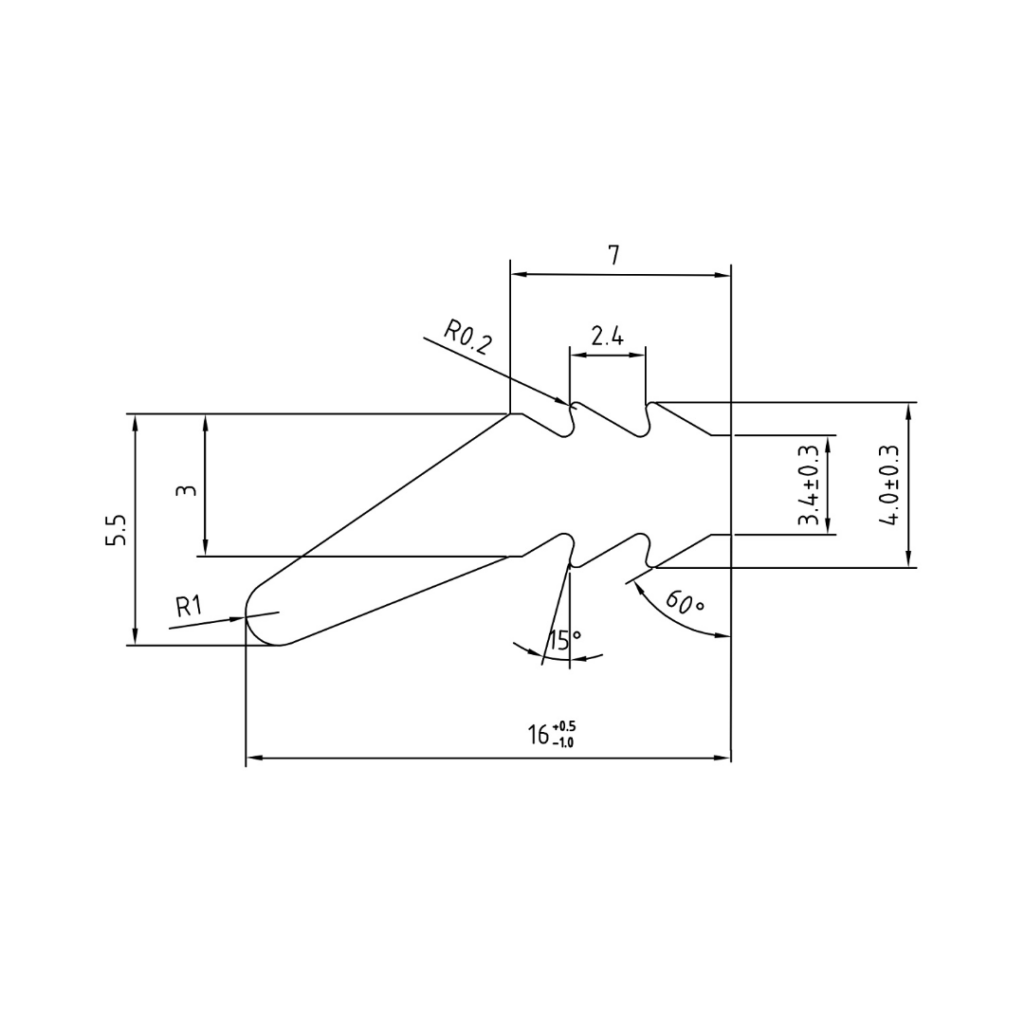

We manufacture cross-roller slewing bearings from the 11 series with a raceway diameter of up to 5000 mm and a roller diameter of 80 mm. They have a single-row roller raceway of 45° and are characterized by uniform resistance to rotation under different loads and higher dynamic life compared to ball slewing bearings.

In addition to ball slewing bearings, cross-roller slewing bearings also place higher demands on the stiffness and accuracy of the connecting structure.

Applications: Robots, antennas, medical technology, machine tools, positioning devices, filling machines, packaging machines.

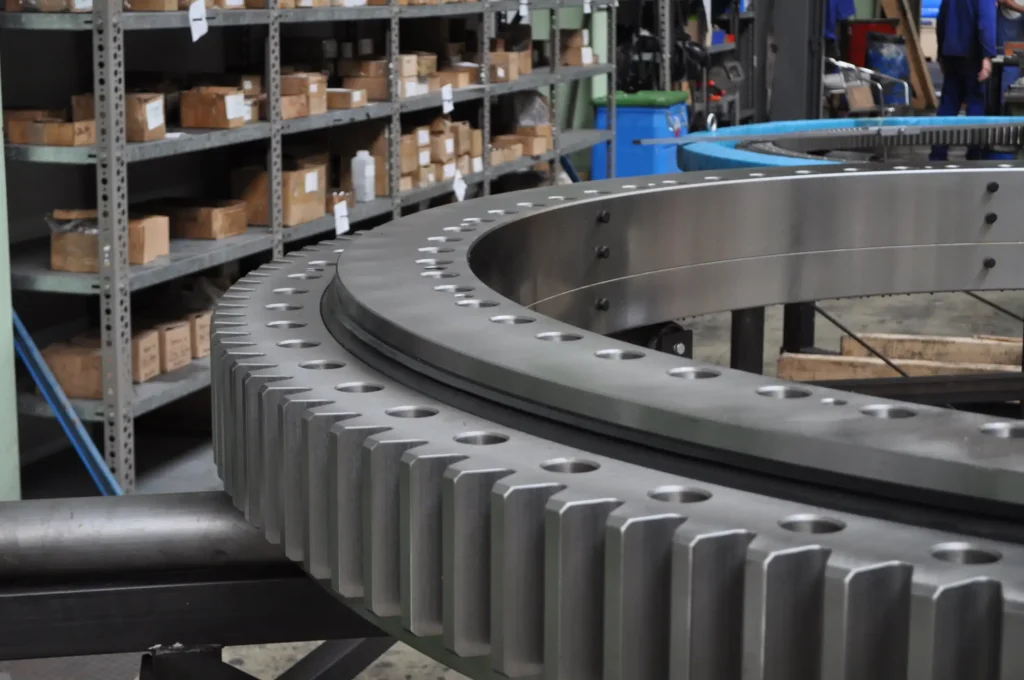

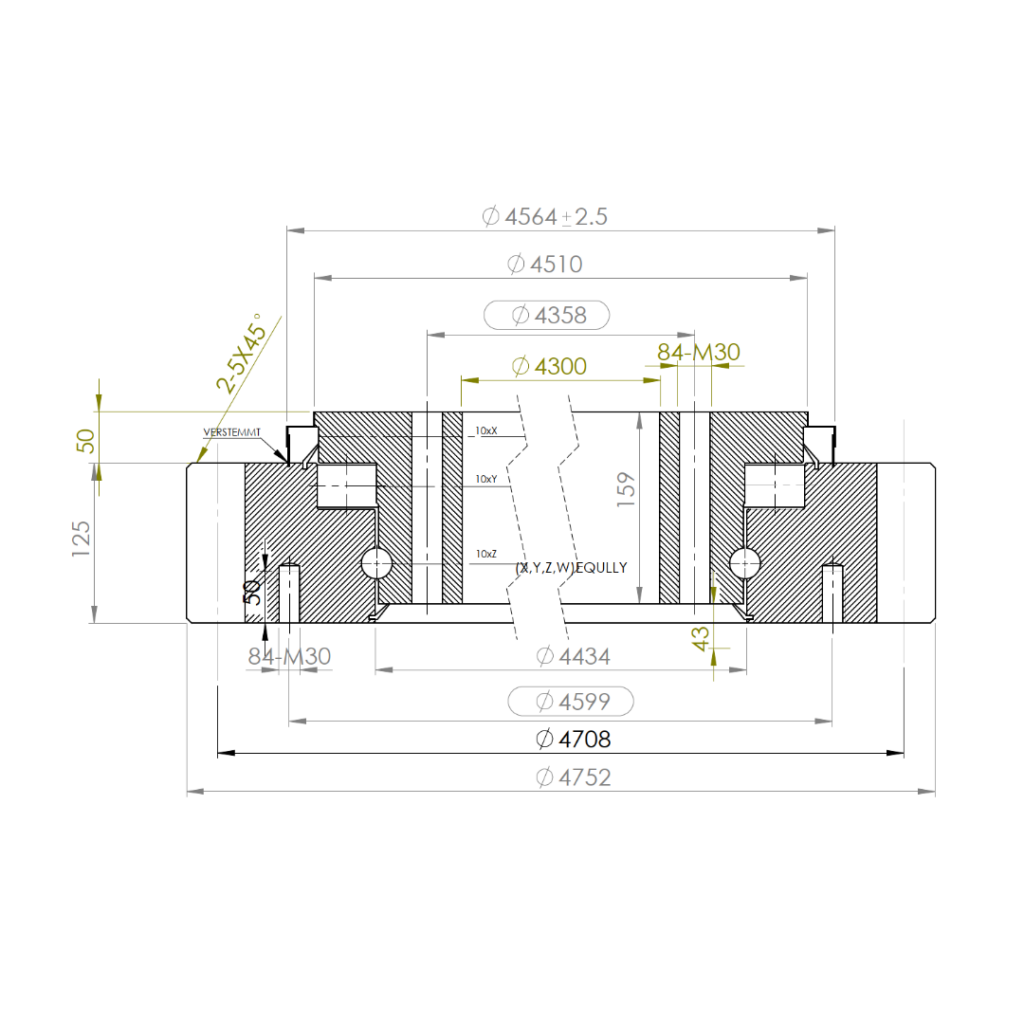

Three-row roller slewing bearings are designed for applications with high loads and low space requirements.

The 13 series is characterized by the highest dynamic load capacity, the highest rigidity, and the most uniform rotational resistance of all types of slewing bearings (with an unchanged raceway diameter). Furthermore, due to the balanced load distribution, the highest demands are placed on the accuracy of the connection structure.

The series offers a diameter of up to 6,300 mm. As a segment design, even up to 14 meters in diameter. Available with plastic spacers or a closed cage depending on the load requirements. The cages are available in various materials such as plastic, steel, and brass.

Applications: deep drilling machines, fire engines, articulated buses, steelworks, self-loading vehicles, cranes, ship loaders and unloaders, port and shipyard cranes, crawler cranes, offshore technology.

The combination bearings from CRB, which are two-row ball and roller bearings, are designed for very high axial loads. This series is usually used when large diameter versions are required.

Depending on customer requirements, we offer the combination bearing in various diameter sizes and any desired configurations.

Applications: Construction machinery, mining equipment, wind turbines, ship loaders, and other offshore applications.

CRB has a machine park consisting of CNC turning, milling, drilling machines, and 5-axis machining centers in Leverkusen, capable of processing workpieces up to 10 tons and a diameter of up to 2.5 meters.

It is possible to manufacture various components for different requirements, such as rolling elements, slewing rings, and seals.

We welcome your requirements and work towards developing and growing together with you.

Consider CRB as your extended purchasing arm to East Asia

We would be happy to advise you on your project. Please feel free to contact us without any obligation.

©2023 All Rights reserved